Products

—Pyrotherm X1

Water-based intumescent coating system for steel components

Description

Pyrotherm X1 is water-based intumescent coating system, requiring less coating to cover structural steel for 240 minutes fire protection. It’s also very easy to apply, promoting greater efficiency during application.

Free from halogens, APEO, borates and plasticizers.Non-VOC acc. to ISO 11890-2, VOC-emission class A+, LEED v4 VOC-emission classification. The tested product is classified to VOC-emission class A+.With rigorous fire testing, approval and certification to meet and often exceed the most stringent of leading global test standards, It is the most efficient thin film waterborne intumescent coating for 240 minutes fire protection available anywhere in the world.

Special Benefits / Performance Features /

Optimal surface appearance by application with airless spraying achievable; long fire resistance rates with low layer thicknesses; maintenance-freeSmooth surface and low coating thicknesses, easy to applyApproved also for the use on galvanized profiles.

Top coat in RAL / NCS or individual colour shades available

Suitable for shop application ( fast drying )

Physical life according to ETAG No. 018-1 up to 30 years, can be prolonged for special projects

Fire resistance rates up to 240 minutes according to UL 263

For open steel profiles: 120 minutes up to Hp / A 450 m-1 , unrestrained beam ratings 180 minutes up to Hp/A: 156 m-1,hollow profiles up to Hp / A 425 m-1 and restrained beam ratings 240 minutes up to Hp/A: 77 m-1 – W/D = 1,74 ( Tcrit. 500 °C )

Specific gravity: 1,42 kg/L, volume solids: 75 % ± 2 % ( measured acc. to ISO 3233 )

Verifications / certification/ Approved elements

Approval / Classification

1.Approved according to DIN EN 13381- 8

2.ETA No. 12 / 0050 ,ABS, BV, DNV, LR, KMERI,

3.Certificate of Applicability for steel tension members with circular cross-section

4.Test on flammability according to IMO, MPA DD

5.CE marking according to 93 / 68 / EWG,

6.ASTM E-84, ISO 834, ISO 22899, ISO 20340,,

7.BS 476,UL 1709, UL 263 , GASAFE,

8.China GB 14907, and Russian GOST

9.Environmental product declaration: EPD-RHG-20140057-IAA1-DE

Technical Information/Application Install locations and dimensions

Application

Before application stir up thoroughly with slow speed. If needed thinning with max. 5 % water. Immediate cleaning of equipment after use with water.

Rolling by lambskin or foam roller, brushing with long-bristled Chinex-bristle

A material temperature of about + 25 °C is recommended for achieving an optimal spraying behaviour and result

Airless Spraying,

• Recommended operation pressure 200 – 250 bar

• Nozzle size 0.016”– 0.024”; flow rate > 4 L/min

• Recommended coverage rate for the 1st layer on a primed surface 500 g/m² ( approx. 250 µm dry film thickness )

• Each further layer can be applied with up to 1,000 g/m² ( approx. 500 µm dry film thickness )

•Typical coverage rate of Pyrotherm X1 applied in one layer depends on the type of steel profile and the position within construction

Drying Time

• The drying time depends on temperature and relative humidity

• At a temperature of approx. + 25 °C and a relative humidity of approx. 55 % the drying time for each layer ( up to 1,000 g/m² ) is at least 24 hours till next application

• Each layer must be dried through ( fingernail test positive ) before the next application

• Lower temperatures, higher relative humidity and insufficient air movement can prolong drying time

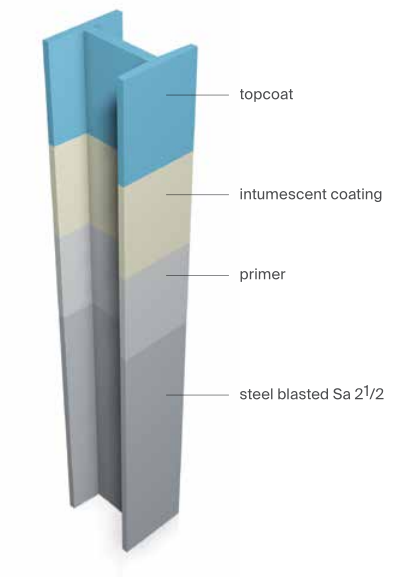

System components/Surface Preparation

Surface Preparation / Primer

Before the application of Pyrotherm X1 already primed surfaces must be checked for damages and dry film thickness if they have been exposed to the weather for longer. If necessary, repair work is needed.

Bare Profiles

•Sandblasting, then application with a two component epoxy primer. In case of epoxy zinc rich primer or other primer chemistry, recommended for cast steel

• Pyrotherm X1 is designed to be applied over suitable-prepared and primed substrate

•The compatibility between Pyrotherm X1 and unknown already applied primers need to be checked; any damage ( corrosion, impact e.g.) must be repaired carefully with the particular typeof primer used or other compatible primers

Galvanized Profiles

• Surface has to be cleaned to remove contamination and to ensure adhesion, then priming with a two component epoxy primer. In case of epoxy zinc rich primer or other primer chemistry,

• Galvanized components must be tempered (heated) before coating with Pyrotherm X1

Areas of Application/ Building materials/ component

Pyrotherm X1 the superior cellulosic fire protection solution

For indoor use only

• For vertical and horizontal load-bearing structural steel , steel profiles as columns,I/ H sections.

•Airports • Shopping centres • Sports stadia• Office buildings • High-rise buildings• Multi-purpose development blocks • Energy industry

•Open steel profiles: R 15 – R 150 for columns, beams and tension members ( utilization factor in cold condition ≤ 78 % ). Hollow profiles: R 15 – R 180 for columns. Up to 2 hours on open steel profiles and hollow sections

• Indoor use without top coat, approved for Interior General Purpose and Interior Conditioned Space according to UL 263.Usable without top coat in dry indoor conditions• Top coatings for finish and aesthetic purposes available

• Durability semi exposed for indoor use and in open buildings without driving rain and condensation

•Structural steel, machine-building-steel ( class E ) is not permitted

•Coated steel components shall not be receive coverings or miscellaneous jackets which prevent the intumescent fire protection coating from foaming / expanding. Only those components may be connected force-fit, which comply with the same fire resistance rate.

Intumescent coatings work by expanding at high temperatures,from a very thin, lightweight coating, into a thick, foam-like layer that insulates the steel from the fire and it is this insulation that maintains the steel’s stability. As a result, Pyrotherm X1 intumescent coatings provide the vital extra time to help people escape and allow fire fighters to save the building itself.