Products

—Description/ Through penetration firestop systems

Pyromastik X9

Integrated Fire Protective Coating System

Description

Pyromastik X9 fireproofing coating for nonexpandable steel structures.It is a spray or trowel applied factory controlled premix based on vermiculite and bauxite cementitious. Only the addition of water is required on the jobsite to form a cohesive, pumpable slurry. Low density,spray applied fire resistive cementitious that is accelerate during the application process to obtain maximum yield and a quickset finish.

Pyromastik X9 produces a monolithic coating able to withstand the thermal shocks experienced in a high intensity hydrocarbon fire. Concrete structures in particular, will be protected from explosive spalling when coated with Pyromastik X9. Although low in density, thus significantly reducing dead load, Pyromastik X9 is highly durable and will not crack or spall under mechanical impact.

Pyromastik X9 is used for application on construction elements such as individual steel or concrete sections particularly where off-site application is required. It is also suitable for use on structures and vessels in the oil, gas, petrochemical and power industries.

Pyromastik X9 will not fail suddenly after the prescribed fire resistance period but will continue to offer a predictable level of fire protection for240 minutes of fire resistance.

It is ideal for application by trowel in interior and fully exposed environments.

Special Benefits / Performance Features /

• Superior insulation properties when exposed to fire

• Improved surface finish, strength and fire insulation

• Impact resistant

• Better workability, easier to scribe and install

• Better fire insulation than that provided by either traditional matrix engineered mineral or gypsum.

• Over 30 years service.• Fire resistance rates up to 240 minutes

•The effectiveness of Pyromastik X9 will not be impaired or destroyed by the effects of water impingement/thermal shock from fire hoses or sprinkler systems. It will remain in place and not be affected by wind turbulence.

• Resistant to impact damage thus able to meet the specification within environments where durability is essential.

• May be levelled to present a trowelled finish.• Can be easily removed and reinstated locally when additional fixings are required.

Durability - cement binder provides increased durability in interior environments where high-traffic resistance to physical abuse is required.

Moisture resistant - Provides excellent resistance to high humidity and condensation.

Applicator friendly - Low pumping pressures allow use of small diameter hoses for increased maneuverability and greater pumping distances.

Non-toxic - The factory-mixed blend of common Portland cement Plaster and inert materials require only the addition of water for mixing and application.

•Low installed weight• Self-reinforced technology• Low water uptake• Resistant to blast overpressures up to 4 bar

Verifications / certification/ Approved elements

BS 476 part 20/21, UL 1709, UL 263, UL723,CAN/ULC-S102

ASTM E84,ISO 834, ISO 22899, ISO 20340, DIN 4102

EN 13381-8, IMO FTP Code, GASAFE,

China GB 14907, and Russian GOST UNI 11076

CE marked product with European Technical Assessment ETA-18/0890

Reaction to Fire: Class B-s1, d0 (EN 13501-1)

Durability and Serviceability: Z2, Z1, Y (EAD 350402-00-1106)

Technical Information/Application Install locations and dimensions

Application

Pyromastik X9 shall be mixed with water at the job site.The material shall not be used if it contains partially set, frozen or caked material.

Conventional, plaster-type mixer or a continuous mixer specifically modified for cementitious fireproofing may be used. The mixer must be kept clean and free from the last mixing material. The mixing speed of traditional mixer should be adjusted to the minimum to allow sufficient mixing.Using proper measuring device and traditional mixer, add water at the same time as the blade turns. Keep mixing until the mixture is free of lumps, with a creamy texture. All raw materials should be completely wet and the mixing time should be about 2 to 5 minutes until the mixture is free of lumps . Target density of 38 to 45 pcf (618 to 702 kg/m 3) is most desirable. Excessive mixing will reduce the spraying efficiency pumping rate and will negatively affect in-place density and mechanical properties.

The minimum average density shall be that required by the manufacturer, listed in the UL Fire Resistance Directory for each rating indicated, as required by the authority having jurisdiction, or minimum average 23 lbs/ft3 (380 kg/m 3), whichever is greater.

The correct adhesion force, density and appearance can be obtained by controlling air pressure at about 20 psi with a nozzle of correct size.

Note: if Pyromastik X9 cannot stick, it is because there is too much mixing water, improper thickness control or the substrate is not clean.

Application of Pyromastik X9 fireproofing can be made in the following sequence:

1.Before spraying Pyromastik X9 onto the roof deck, a ground layer should also be sprayed. Mechanical reinforcement must be attached to the substrate with mesh where vibration or mechanical damage and the possibility of subsequent de-bonding exist .The construction of the ground floor shall be in accordance with the construction specifications of the material supplier.

2.It is recommended that the total required thickness be applied within a 24 hour period. If this is not possible, the preceding coats should be left as sprayed or scored after the initial 24 hour period; Pyromastik X9 should then be dampened with water before application of additional coats.

Pyromastik X9 is applied directly to the steel, at various rates of application which will be job dependent, using standard plastering type equipment or continuous mixer/pump units. A spray gun, with a properly sized orifice and spray shield and air pressure at the nozzle of approximately 20 psi (138 KPa), will provide the correct hangability, density and appearance. NOTE: If freshly sprayed Pyromastik X9 does not adhere properly, it is probably due to a too wet mix, poor thickness control, or an improperly cleaned substrate.. If a smooth finish is required, trowel, roller or brush may typically be used within an hour of final application .

Temperature & Ventilation

The substrate temperature shall be a minimum of 41°F (5°C) for at least 1-hour prior to the application of the Pyromastik X9 . Additionally, the air and substrate temperature during application and for a minimum or 24 hours after application shall be range from 41°F (5°C) to 131°F (55°C).

Provisions shall be made for ventilation to properly dry the fireproofing after application. In enclosed areas lacking natural ventilation, air circulation and ventilation must be provided to achieve a minimum total fresh air exchange rate of 4 times per hour until the material is substantially dry.

System components/Surface Preparation

Steel and Concrete Surfaces

Prior to the application of Pyromastik X9 Fireproofing, an inspection shall be made to determine that all steel and concrete surfaces are acceptable to receive fireproofing. The steel to be fireproofed shall be free of oil, grease, excess rolling compounds or lubricants, loose mill scale, excess rust, non-compatible primer, lock down agent or any other substance that will impair proper adhesion. Where necessary, the cleaning of steel surfaces to receive fireproofing shall be the responsibility of the general contractor.

Prior to application of Pyromastik X9 a bonding agent approved by the fireproofing manufacturer shall be applied to all substrates to receive Pyromastik 9. There are two exceptions to this requirement;

1.no bonding agent is required when Pyromastik 9 is applied uninjected to bare steel, and

2.no bonding agent is required when bond tests run in accordance to the Coatings Materials section of the Underwriters Laboratories Fire Resistance Directory Volume 1, which indicate that a bonding agent is not required for Pyromastik X9 in conjunction with the specific primed or painted structural steel.

The project architect shall determine if the painted/primed structural steel to receive fireproofing has been tested in accordance with ASTM E119, to provide the required fire resistance rating.

No fireproofing shall be applied prior to completion of concrete work on steel decking.

Fireproofing to the underside of roof deck assemblies shall be done only after roofing application is complete and roof traffic has ceased.

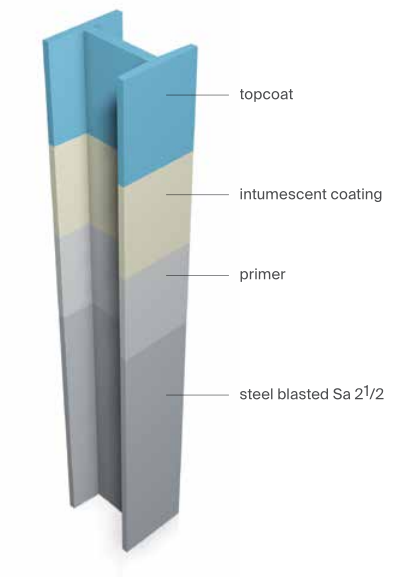

Top coating

Under certain circumstances, Pyromastik X9 and/or other nominated top coatings may be used as protection from frequent wash down, long term chemical spills, or for improved resistance to fungal, algal and bacterial growth.

A primer must be applied to the steel sub- strate. Contact GC Technical Services.Department for a complete list of approved primers.

Pyromastik X9 can be brushed or sprayed, not rolled. It is available in a trowel grade material.

The applied thickness of Pyromastik X9 will depend upon the specified fire rating and size / shape of the steel member to be protected.If desired, a finish coat may be applied in the desired color and finish directly over Pyromastik X9 in accordance with the guide- lines noted in our Finish Coat Materials data sheet.

Areas of Application/ Building materials/ component

For interior and exterior exposed

Pyromastik X9 may be used in parking garages, exterior areas, mechanical rooms and other areas where a highly durable product is required.

Pyromastik X9 design is commonly used for structural steel columns, beams, joggers, flooring and steel plates. For use in the onshore oil, gas, petrochemical and power generation industries under certain specified conditions.For in situ applications to pre-erected structures, to provide protection from the effects of hydrocarbon pool and jet fires.

Durability semi exposed for indoor use and in open buildings without driving rain and condensation. For vertical and horizontal load-bearing steel profiles.For open steel profiles, H / I- beams and columns .Top coatings for finish and aesthetic purposes available

For vertical and horizontal load-bearing structural steel , open steel profiles as columns,I/ H sections. Special use areas in commercial buildings,Transportation terminals,Convention centers,Stairwells,Parking garages,Elevator shafts,Light manufacturing areas and facilities,Mechanical rooms,Gymnasiums and pool areas,Correctional facilities